Slab Headboard - 20 For Sale on 1stDibs | slab wood headboard, wood slab bed frame, wood slab headboards

Amazon.com: Joy Toy 65982 Figures and Miraculous Charm Bracelet Characters on Backercard 15X1X9 cm Girls : Toys & Games

Custom Projection Photo Bracelet ,birthstone Bracelet ,women's Jewelry Gift ,her Gift ,wife Gift ,girlfriend Birthday ,anniversary Gift - Etsy

Amazon.com: ZAG STORE - Miraculous Ladybug - Purple Tigress Bracelet, Pink,Purple: Clothing, Shoes & Jewelry

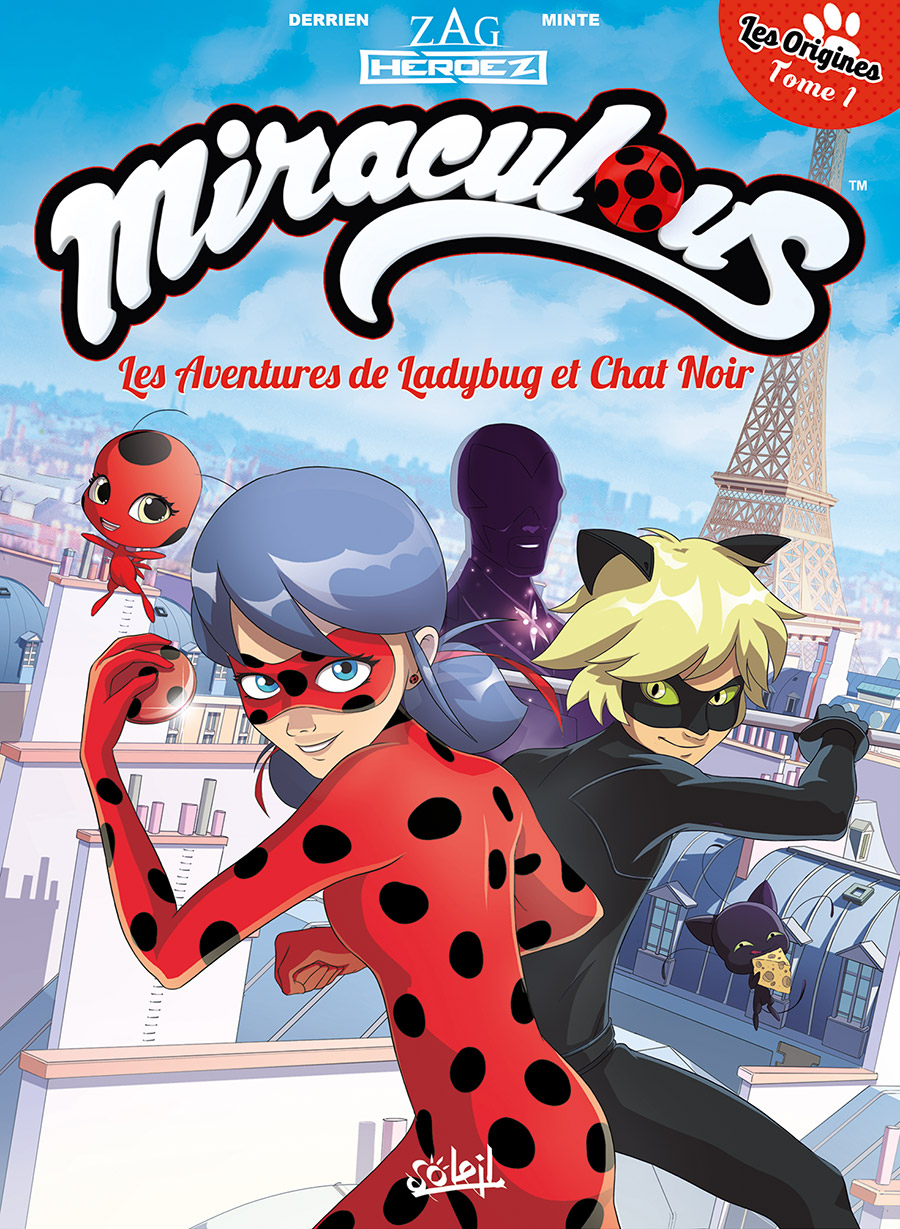

DIY Tutorial: Master Fu Jewelry Box and All Miraculouses of drawers - Miraculous Ladybug Compilation - YouTube

Amazon.com: Joy Toy 65982 Figures and Miraculous Charm Bracelet Characters on Backercard 15X1X9 cm Girls : Toys & Games

READY MADE Resin Loli Rock Princess Cosplay Necklace - Etsy | Bijoux magiques, Beaux bijoux, Collier

Earrings: Little Red Riding Hood. Boucles D'oreille, En Métal Argenté, Le Petit Chaperon Rouge Et Le Loup. Bijoux Enfant Ou Adulte. - Etsy

Amazon.com: Miraculous Ladybug Jewelry Set for Girls - Bundle with Miraculous Ladybug Charm Bracelet, Earrings, and Stickers (Miraculous Ladybug Bracelet Set) : Toys & Games

Madonna and Child Christmas Tree Ornament | Algiers Point Oyster Co. – Beatrixbell Handcrafted Jewelry + Gift

Amazon.com: ZAG STORE - Miraculous Ladybug - Purple Tigress Bracelet, Pink,Purple: Clothing, Shoes & Jewelry

DIY The new MIRACULOUS LADYBUG REVEALED - How to make DRAGON HOLDER Watch of IKARI GOZEN episode - YouTube

DIY The new Miraculous Ladybug | How to make Tiger Miraculous panjas bracelet with rings Roaar Kwami - YouTube

DIY Miraculous Ladybug COMPILATION | Make PIG bracelet | OX piercing | TIGER panjas and DOG Necklace - YouTube

Amazon.com: Miraculous Ladybug Jewelry Set for Girls - Bundle with Miraculous Ladybug Charm Bracelet, Earrings, and Stickers (Miraculous Ladybug Bracelet Set) : Toys & Games

New Miraculous Girl Ladybug Reddy Black Cat Roll Anime Card Badge SSP TCP Children's Game Toy Christmas Halloween Birthday Gift - AliExpress

Miraculous Ladybug Jewelry Set for Girls - Bundle with Miraculous Ladybug Charm Bracelet, Earrings, and Stickers (Miraculous Ladybug Bracelet Set) : Toys & Games - Amazon.com

Barbara Nameplate Necklace For Women Stainless Steel Jewelry Gold Plated Name Chain Pendant Femme Mothers Girlfriend Gift - Necklace - AliExpress

Amazon.com: Miraculous Ladybug Jewelry Set for Girls - Bundle with Miraculous Ladybug Charm Bracelet, Earrings, and Stickers (Miraculous Ladybug Bracelet Set) : Toys & Games